Configuring and programming igus linear robots – as easy as playing PlayStation

May 12, 2022

Gamification approach and additional features make online configurator for low-cost linear robots even more intuitive

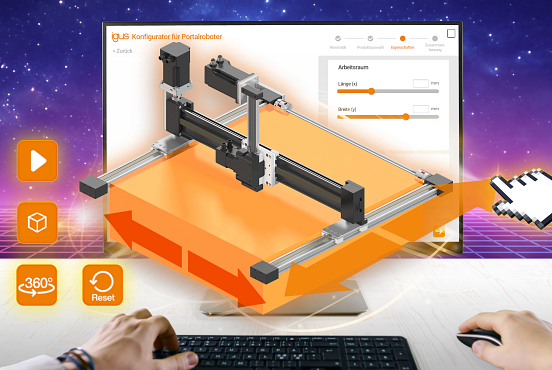

With the help of the game engine Unity, motion plastics specialist igus has given its online configurator for low-cost linear robots a facelift, making its operation even more efficient. Now, users can configure an individual linear robot ready for connection faster and easier – in just five minutes and with instant price information. With the help of the online tools, any automation solution can be programmed and tested directly in the selected working area and also load CAD data and a suitable drawing. Even small and medium-sized companies can immerse themselves without a barrier in the world of automation – without the know-how of specialists and CAD software.

Increase efficiency, reduce errors and lower costs: many companies are recognising the benefits of process automation. But choosing the right robot can be time-consuming – and time is money. Last year, igus developed an online configurator to make it easier getting started with automation. With just a few clicks, customers can easily configure ready-to-connect low-cost linear robots based on sliding drylin linear guides. Linear robots are available without control system from 1,000 euros per unit, and with control system and software from around 4,000 euros. “Since the launch of the configurator, we received a lot of positive feedback on the gamification approach and intuitive usability,” says Alexander Mühlens, head of the Automation Technology and Robotics division at igus. “Nevertheless, we asked ourselves: Can we continue to improve operation with this feedback? The answer was a resounding yes. As a result, we have further optimised the configurator and added new functions.”

Configure individual robots — even easier thanks to the gaming platform

For the new design of the configurator, the igus developers used Unity – a platform used in the development of games for PC and game consoles. Operation of the configurator is correspondingly intuitive. And it works as follows: in the first step, the user selects the kinematics, i.e. a line, flat or room linear robot. The view is reminiscent of a selection menu from a computer game, which players use to select racing cars, for example. With these standard configurations, the right robot can be quickly selected under clear conditions. For the first time,. it is now possible to compile and enquire about a special linear robot. Whether ice cream maker, measurement system or palletising robot: many applications need to meet special safety regulations,for example, be splash-proof or work in very small installation spaces. The online configurator allows users to request a special linear robot that meets the specific requirements of their individual application.

3D model visualises the installation space and movements of the linear robot

The next step: configuring the linear robot. Sliders are available here, which can be used to set the stroke lengths of the X, Y and Z axes with millimetre precision. A dynamic 3D model of the linear robot, which can be rotated in all directions, visualises the settings in real time. “We have added a new function at this point,” says Mühlens happily. “With one click, it is now possible to also display the installation space of the linear robot. We use coloured areas for this. This gives users a visual impression of how much space their automation solution takes up.” To ensure transparency in terms of costs, users also receive an instant display of the price of their automation solution. Advanced users can also export the 3D model as a STEP file and process it further in any CAD program. With the online configurator, it is even possible to define robot movements – by entering a few parameters and without programming knowledge. “With this function, we follow the motto ‘Test before invest’. Thanks to the moving 3D model, operators gain a feeling for robot movements and cycle times,” says Mühlens. After online programming, the file can be displayed in virtual reality via an app or loaded into the real robot control system.

Ordered online: a short time later the robot is delivered

If operators are satisfied with the configuration of the linear robot, the next steps to follow are: they select a suitable control system that completes the linear robot into a ready-to-connect low-cost robotic solution – whether ready-to-use with igus robot control or the do-it-yourself version with a D1 dryve control system kit. Shortly after ordering online, the automation solution is delivered. Pre-assembled linear robots in standard sizes are even ready to ship within 24 hours. Another plus: T hanks to the self-lubricating igus polymers, all configurable linear robot systems are 100% maintenance-free and clean in all bearing points. And additional components such as grippers, vision systems, motors and sensors are available to automation novices via the Low Cost Automation marketplace RBTX.