When the robot writes the greeting card

February 10, 2025

US engineering firm implements handwriting robots with maintenance-free linear and lead screw technology from igus

E-mails, instant messages, printed greeting cards: communication in the business world quickly takes on an impersonal flavour. A robot from the company Spline Product Development in Arizona wants to change this. Thanks to maintenance-free linear technology from igus, it is able to write cards in human handwriting, making messages more emotional and ensuring greater resonance.

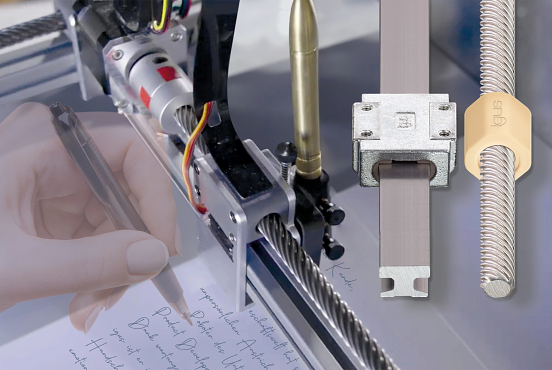

A personal greeting card from your favourite online shop? Recipients in the USA are currently receiving exactly this type of special advertising mail. The engineers at Spline Product Development make it possible. The handwriting robot from the US developers looks like a compact 3D printer. At its heart are three linear axes that enable the movement of a biro. The positioning is so precise that the robot can even imitate the nuances of predefined handwriting. It is designed for companies that want to send their customers letters with a personal touch. According to marketing experts, these receive a much greater response than sober-looking letters from a classic printer. The handwriting robot is currently being used by the provider Simply Noted from Tempe in Phoenix, USA.

igus linear technology allows robots to write as precisely as humans

As elegant and effortless as the robot’s work appears, realising its precise movements was a considerable technical challenge. Earlier models worked, but were slow and susceptible to wear. That led to high maintenance costs, according to the Spline Product Development engineers. The writing results also left a lot to be desired. The experts only achieved significant progress by using the linear technology from igus. The solution is a combination of miniature aluminium linear guides from the drylin T miniature series with pre-loaded linear carriages, a dryspin lead screw drive and electric stepper motors. Two of the linear guides run parallel at a distance of about 50cm. Linear carriages move on their rails, holding and vertically positioning a third linear guide. The pin is mounted on another carriage that moves horizontally on the third linear guide. Thanks to the synchronised interaction of the axes, it can reach any point in the writing area. When the pen starts to write, maximum mechanical precision is required. “The stepper motors realise precise movements of the carriages in the millimetre range via the lead screw drives in millisecond cycles,” explains Michael Hornung, Product Manager drylin Linear and Drive Technology at igus. This high level of precision is made possible by the innovative geometry of the dryspin lead screw thread, among other things. The flank angles of the lead screw nut and lead screw are flat, resulting in an above-average efficiency of 82%, which supports the adjustment accuracy. “It is this adjustment accuracy that enables the robot to write with the same fine motor skills as a human, where over 30 different muscles in the hand, arm and shoulder work together during handwriting.”

One card after the next: freedom from lubrication ensures high reliability

Due to igus linear technology, the handwriting robot is not only more precise, but also requires less maintenance. The reason: the linear guides do not need external lubrication. The high-performance plastics of the lead screw nuts and the sliding elements, over which the linear carriages move on the rails, contain solid lubricants that are gradually released during operation and allow for low-friction dry operation. “Thanks to this self-lubricating effect, the handwriting robot can work without failure even in dusty environments,” says Hornung. “Unlike with lubricated systems, there is no risk of dust and dirt from the environment combining with grease to form a mixture that negatively affects the precision of the adjustment movements.” The robot can therefore write thousands of company greetings without getting tired or calling for disruptive maintenance work.