The plastic bicycle from igus goes into series production with the new name RCYL

April 30, 2024

The bikes from Cologne are made from recycled fishing nets and require no lubrication

The bikes from Cologne are made from recycled fishing nets and require no lubrication

RCYL starts a new chapter in sustainable mobility. The former igus:bike is now called RCYL – a bicycle made from 50 per cent recycled fishing nets. For the moving components, igus relies on its lubrication-free, rust-free and recyclable high-performance plastics – “zero lubrication”. With series production in Cologne, igus is setting a milestone: the plastics company aims to produce 5,000 bicycles by next season. This, however, is just the beginning. The aim is to establish local production at landfill sites around the world and thus close the plastic cycle.

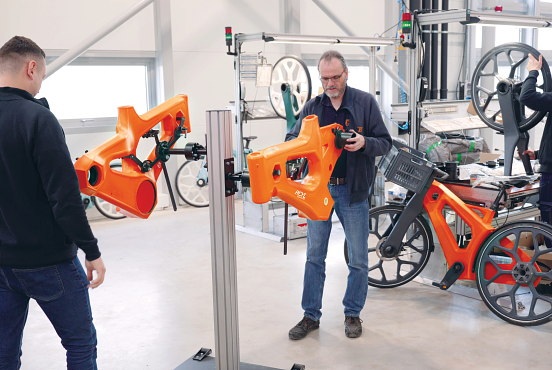

Frank Blase is beaming with joy as he holds the first plastic bicycle produced in Cologne in his hands. After 3.5 years of development, his personal dream of an urban bike made from plastic waste is now a reality that is going into series production. “With the igus:bike, we presented a concept and an idea in 2022. Now, two years later, we have a product ready for series production that we manufacture ourselves,” says the CEO of igus GmbH. “We are delighted to fulfil the first 1,200 pre-orders.” With the start of series production, the bike is given a new name in addition to technical optimisations: the igus:bike has grown into RCYL. “We at igus pronounce it ‘R(e)CYL(e)’. The new name RCYL stands above all for the bike’s recycled content and the sustainability concept behind it. After all, it is made from 50 per cent old fishing nets and is the world’s first bicycle made from recycled plastic,” says Blase. “The igus:bike will remain an ongoing development project. When you see an igus:bike on the road, you know that something completely new is being tried out here.”

Series production starts: 5,000 bikes by June 2025

igus celebrated the fact that the RCYL bicycle is ready for series production at CyclingWorld Europe in Düsseldorf in mid-March. “Trade show visitors were literally queuing up to take a test ride. Both the improved handling and the futuristic design were praised,” explains Sven Terhardt, Head of Sales and Marketing RCYL. The RCYL bike will soon be available for €1,200. But how do you get your hands on the bike? “First of all, we are processing the first pre-orders, which can be made via the contact form on our website igus.bike . We are currently considering setting up a dealer network or opening our own stores in major cities. However, there is one important rule: no RCYL bike will be sold without the option of service. We can also imagine RCYL as a company bike, at trade shows or for hotels,” says Terhardt. By setting up their own production facility, igus aims to produce 5,000 bikes for the next season. By 2026, the target set at 10,000. To achieve this, igus is investing in the development and construction of its own roto-moulding systems. igus is relying on their 60 years of plastics expertise for this special production technology, particularly for processing recycled plastics for highly stable bike components. Here in particular, the Dutch start-up MTRL complements the work of the igus engineers with its expertise, to realise cost-effective series production for wheels and frames.

Plan for the future: bicycle production at rubbish dumps

In future, igus not only wants to provide mobility in German and European cities as well as in the USA. “We also want to set up local production facilities for the RCYL bike in countries where a lot of waste is generated. That way, we want to feed the waste directly into a new cycle. We not only want to close the plastics cycle, but also create jobs and mobility in Africa and South America,” explains Terhardt. igus is also working intensively on the RCYL series itself, including an e-bike version.

RCYL as an innovation lab for bicycle manufacturers

Furthermore, igus is adhering to their plan to offer everything that goes into series production at RCYL to the entire industry as purchased parts. “It’s like a product platform. As we produce all the plastic components used in the RCYL bike ourselves, the manufacturers can also purchase the individual components directly from igus,” says Sven Terhardt. “The entire bike industry can work with our components, build local supply chains, become rust-free, lubrication-free and even more sustainable.”