Technology without compromise: igus presents new PTFE-free and PFAS-tested products at plastics trade show K

October 8, 2025

PTFE-free materials for plain bearings, linear guides and 3D printing have up to 50% lower wear rates

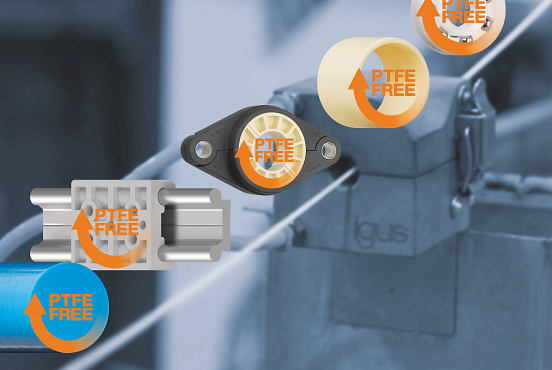

PFAS and PTFE (a subgroup of PFAS) have been present in many products worldwide for decades – whether pans, shoes or hoses. It is due to them that plain bearings, e.g., can operate in dry operation without lubrication. However, the organic fluorine compounds decompose very slowly and can be harmful to people and nature. The discussion about a possible ban is causing uncertainty in the industry. As a pioneer for lubrication-free high-performance plastics for motion, igus recognised this challenge at an early stage and has already developed its own PTFE-free materials. At the K plastics trade show in Düsseldorf from 8th to 15th October, the company will show that this change is not only possible, but can also be linked to technical improvements. October (Hall 5, Stand D05).

Plain bearings, gears, linear systems: igus develops and produces moving components made of high-performance plastics which, thanks to additives, are not only robust and resistant to wear, chemicals and the weather, but also allow for low-friction dry operation without additional lubricants. These additives also include polyfluorinated alkyl substances (PFAS), a group of chemicals that the EU might regulate more strictly in future. “Many design engineers are therefore already looking for alternatives that don’t compromise on functionality and are as cost-effective as possible,” says Lars Butenschön, Head of the iglidur Plain Bearing Technology Business Unit at igus. In recent years, materials scientists at igus have therefore put in a great deal of research and development effort to create PTFE-free materials for components from injection moulding, 3D Printing and bar stock. “We can already offer 27 PTFE-free and PFAS-tested materials that are used in our motion plastics – from energy chains to plain bearings, ball bearings, bar stock and 3D printing materials. They retain their proven specifications despite the changeover, as confirmed by tests in our 5,500m2 metre test laboratory,” says Butenschön.

Successfully tested for PFAS: from plain bearings and linear guides to material for 3D printing

The plastics specialist already offers PTFE-free alternatives for its established polymer plain bearings of the standard iglidur J, W, G, X and H series, which are used in machines, systems and vehicles across the globe. “Since 2025, we have been able to realise around 75% of plain-bearing applications without PTFE,” emphasises Butenschön. They have also been tested for the 96 PFAS considered critical for environment and health and do not contain any substances in concentrations above 0.1% by weight. At the plastics trade show K, igus will be presenting further new PTFE-free products – from ball, joint and slewing ring bearings to gears and linear guides to cables and a new resin for 3D printing. “If the demand for such PTFE-free and PFAS-tested alternatives continues to rise, we will be able to compound larger batches and source raw materials more cost-effectively, thereby further reducing the slight price difference compared to traditional products,” explains Butenschön.

PTFE-free materials even more wear-resistant

Investigations into the friction and wear behaviour have also shown that the iglidur materials with substituted PTFE achieve a significantly better performance compared to reference containing PTFE. Wear rates, for instance, are reduced by up to 50%. The clever design of the formulations also means that the known material properties in terms of temperature stability, mechanical strength and shrinkage behaviour remain virtually unchanged. To drive development further forward, igus is currently expanding its test laboratory for bearing and linear technology alone to three times its current size – and thus to a total area of 1,500m2. Thanks to the test laboratory, an in-house technical centre and intensive research, igus can offer customers and potential users solutions today that might be required by law tomorrow – and that are both more environmentally friendly and technically superior.

Video on the subject of PTFE:

https://www.youtube.com/watch?v=yqFazLJQ_2c