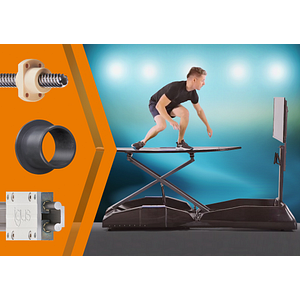

Surfing on land: motion plastics keep people and machines fit

October 26, 2019

Lubrication-free, high-performance polymers save 70 per cent in costs and minimise maintenance in surf machines

For the designers of Surf Evolution, the metallic bearings proved to be too maintenance-intensive and too expensive in their novel surf machines. Looking for an alternative, they quickly came across the motion plastics from igus. And the design engineers were thrilled, because the retrofitting significantly reduced the maintenance and saved 70 per cent in costs.

Among surfers, Brazil is no longer an insider tip. Endless sandy beaches and a multitude of wave formations and bays attract enthusiastic surfers to the numerous beaches and coves, where they plunge into the waves. The Surf Evolution shows that you do not always need water for surfing. The Brazilian company is developing fitness training equipment that simulates the movements of the surf board. Because surfing is an effective total body workout in which a variety of muscles are trained, with this training equipment, non-surfers also benefit from the effective workout. 20 different exercises can be completed in just 2 square metres. And the app provides support, giving the customer valuable training tips. To realistically simulate the complex movements of surfing, the company is now completely relying on the advantages of iglidur’s high-performance polymers. Optimised for friction and wear, igus tribo-polymers fulfil their expectations, especially in terms of cost and maintenance reduction.

Plastic instead of metal

In the first version, the developers still relied on metallic bearings. However, it soon turned out that the cost of the components was too high and, above all, the maintenance of the many bearing points was too time-consuming. Therefore, the training equipment was redesigned and the bearing technology was systematically replaced. The numerous bearing points are now equipped with iglidur plain bearings. The load setting now uses lubrication-free and maintenance-free drylin lead screws. Smooth movements of the board, forward and backward, are ensured by the drylin W linear guides from the motion plastics specialist. This not only enabled improved maintenance, but also cost savings of 70 per cent.

The following video offers an overview of the various training options: https://www.youtube.com/watch?v=VrnGW3VNS5I