speedigus service: the quick way to customised wear-resistant parts from igus

Published on: 19th July 2019

Prototype and high volume production made of tribo-polymers manufactured quickly using various manufacturing methods

speedigus service: the quick way to customised wear-resistant parts from igus

speedigus service: the quick way to customised wear-resistant parts from igus

Prototype and high volume production made of tribo-polymers manufactured quickly using various manufacturing methods

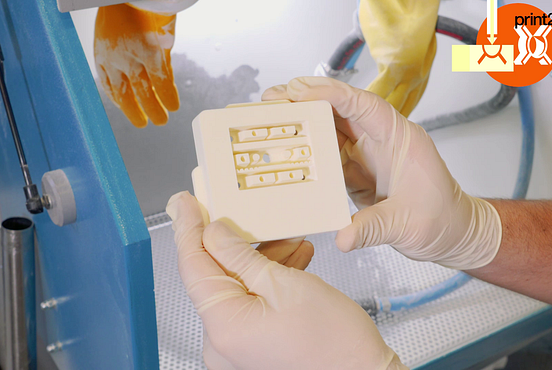

In order to be able to quickly supply and install the right plain bearing solution at all times, igus keeps more than 12,000 different iglidur plain bearing types made of tribo-polymers in stock. But sometimes customers demand plastic components which are not in the catalogue. For this purpose, igus manufactures customised parts using various methods. The type of production is determined by the motion plastics specialist according to the required quantities. For large volumes starting at 500 pieces, the in-house tool manufacturer constructs application-related moulds made of steel, which are then used in the injection moulding machines. For small batches up to 500 pieces or prototypes, igus offers another solution for wear-resistant special parts via the speedigus production service. The speedigus services are divided into the speedimold, speedicut and speedifit divisions and the 3D printing service – according to the method that is most suitable for the respective application. In the video, Gerhard Baus, Vice President New Business Development, tells you what is possible with the different methods: https://youtu.be/x8H9WISW9gQ