Small, compact and cost-effective: new lubrication-free toothed belt axis from igus

Published on: 22nd May 2019

Lightweight and compact toothed belt axis ensures Low Cost Automation in the tightest of spaces

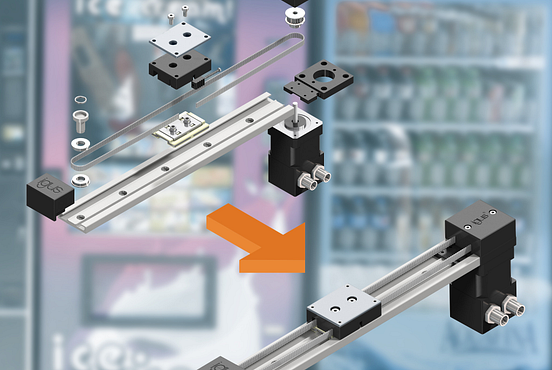

Fast automation in confined installation spaces: igus has now developed an extra-compact toothed belt axis based on its flat drylin N linear system. The new axis consists of a completely standard fitment of components and is thus easily assembled within a few minutes and cost-effective. Equipped with motor and control, the new system can carry loads of up to 20 Newton and a translation of 60 millimetres per revolution.

From the lubrication-free plain bearing and the maintenance-free linear guide up to the completely ready-to-install linear robot, igus develops solutions for the industry with its plastics – either as a single part or as a system. With the help of its linear construction kit, the motion plastics specialist has combined its drylin N low-profile linear guide with a toothed belt and has now developed the new cost-effective drylin ZLN toothed belt axis as standard. Whether in vending machines, service robotics or even in automation systems, the new compact toothed belt system can be installed quickly and easily in the smallest of spaces. The flat drylin N linear guide ensures compact construction, which is just 27 millimetres high and 40 millimetres wide. The toothed belt mounted on ball bearings enables high speed dynamics. With the combination of low-profile linear guide and toothed belt, loads up to 20 Newton can be moved vertically at a ratio of 60 millimetres per revolution. By using high-performance polymers in the sliding carriage, users can completely dispense with lubricants and thus the maintenance of the unit. Moisture, dirt and dust are no problem for the drylin ZLN: great advantages, especially for machines that are in use 24/7.

Plug in, install, low cost

The new toothed belt axis for Low Cost Automation consists of standard components from the drylin modular system that can be fitted together and assembled quickly. Thus, the new axis is not only lightweight due to the use of plastic components, but also cost-effective and delivered quickly. A completely ready-to-install drylin ZLN can be ordered with NEMA stepper motors or with EC/BLDC DC motors as well as a suitable dryve control system. The new, cost-effective toothed belt axis can be delivered in the desired size with a maximum length of up to 750 millimetres already from 24 hours.