Simple connection to machine construction profiles: new drylin ZLX toothed belt axis from igus

June 25, 2024

drylin ZLX is suitable for all handling tasks up to a stroke length of 3,500mm and is available ready for connection

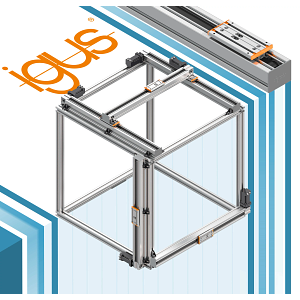

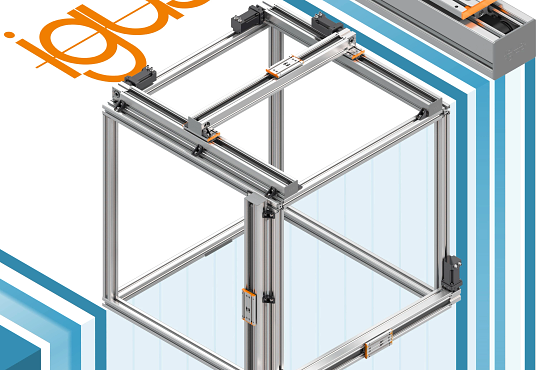

The motion plastics specialist igus is expanding their drive technology range with new toothed belt axes: the compact, robust and lubrication-free drylin ZLX high-performance series. The anodised aluminium profile of the axes has been developed in a completely new geometric design. As a result, drylin ZLX not only looks like a mechanical engineering profile, but can also be quickly and easily integrated into a modular profile system. With a load capacity of 150N and speeds of up to 3m/s, the new toothed belt axis is suitable for automated production lines, pick-and-place systems and 3D printers, among others.

With drylin ZLX, igus relies on proven technology in a new design: the heart of the new toothed belt axis is a linear guide system from the drylin W series, installation size 16, which is integrated into the interior of a robust, corrosion-resistant and clear anodised high profile. In contrast to the other igus axes, the toothed belt to which the carriage is attached runs inside the profile. As a result, the axis looks like a mechanical engineering profile. However, the design also has a technical advantage: “Classic aluminium profiles have very specific dimensions, and there are also standards for the grooves, which our drylin ZLX fulfils,” explains Stefan Niermann, Head of the drylin Linear and Drive Technology Business Unit at igus. “Thanks to commercially available slot nuts and connecting elements such as brackets, it’s easy to combine it quickly with standard mechanical engineering profiles in a kind of modular system. This is particularly useful for linear robot structures. And thanks to the new design, everything looks as if it has been cast from a single mould.” Customers therefore benefit from a standardised design and reduced assembly times. In addition, you can adjust belt tension on the new axis directly on the carriage without dismantling any components – simple and quick with an adjusting screw.

Quiet, lubrication-free, robust

drylin ZLX is quiet, robust and, like all igus axes, runs without lubricant over the entire stroke length. The company also relies on the principle of “sliding instead of rolling” for the new toothed belt axis. Guide systems work over a large area on the rail or shaft. Due to the larger contact surface and lower surface pressure, it is possible to use plastic components and softer materials such as aluminium. This not only makes the design lighter, but also allows it to run quietly. The carriage moves over lines made of the tribopolymer iglidur J200, which offer a long service life with fast and slow adjustments. The solid lubricants integrated into the high-performance plastic are released when the axis is running and enable maintenance-free dry operation. To improve performance, the designers have optimised the ratio between the dimensions of the guide system and the deflection. Larger deflection radii improve the wear resistance of the toothed belt as it is subjected to less bending and therefore less stress. At the same time, the installation size 16 of the drylin W linear guide ensures longer axis service life. “We have optimised the guide system for the installation space. Large gliders mean a larger contact surface, which in turn enables a higher load capacity,” says Niermann. drylin ZLX is suitable for loads of up to 150N and has a stroke length of 3,500mm. Tests have also revealed that it achieves a running performance of up to 20,000km without maintenance with a horizontal load of 5kg and 0.5m/s, for example. The service life is predictable online.

Ready for connection with gearbox and electric motor

The new toothed belt axis can be used in combination with various linear robot structures as well as in stand-alone operation. A large number of grooves offer various options for attaching accessories such as sensor mounts or protective devices to the profile and carriage. igus supplies the toothed belt axes ready for installation with electric motors and offers a choice of three motor concepts: stepper, EC/BLDC or DC motors. These can all be operated with the D1 universal control system, or with cost-effective drives such as D3, D5, D7, D8 or D9. Thanks to the flexible design of the connection elements, customer motors from other manufacturers can also be attached on request. drylin ZLX is characterised by a precise and rigid motor connection. The drive can be realised via a double expanding mandrel or a plug-in shaft, which increases flexibility when adapting to different applications. Examples of suitable applications include automated production lines, pick-and-place systems and 3D printers. Use the drylin drive technology online configurator to configure the new linear guide in just a few minutes.