One for all: quickly installed igus retaining fixture for more safety with cobots

Published on: 13th June 2019

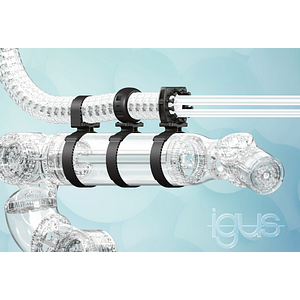

New universal clamp for energy chains and protective hoses ensures increased safety at work with all collaborative robots

New universal clamp for energy chains and protective hoses ensures increased safety at work with all collaborative robots

When people and machines stand shoulder to shoulder in production, safety at work is an important issue. Therefore, igus has now developed a new clamp for energy chains and protective hoses on cobots. The Lean Robotics retaining fixture produced by injection moulding, has a uniform size which makes it very cost-effective. The retaining fixture can be installed in seconds with a Velcro strip. Available in three options, the new clamp allows the universal safe guidance of cables for data and energy.

Cobots continue to be a big trend in production and are used not only by major industrial players, but increasingly also by small and medium-sized businesses. The reason is, the automation of sub-processes ensures that companies can be competitive in the market. The collaborative robots work hand in hand with humans in close proximity. Sensors and cameras as well as an energy supply system ensure the safety of the process. igus has developed the three-dimensional triflex R e-chain series to ensure that cables and hoses are reliably and compactly guided in cobots. For a secure attachment of the energy chain or the protective hose on the robot, the user can now rely on the new Lean Robotics clamps from igus. The universal retaining fixtures with Velcro fasteners are flexible in shape and adapt to any robot arm. A slim design with rounded edges increases workplace safety by reducing the risk of injury when in contact with the robot.

Quick to assemble and cost-effective thanks to plastic

The Lean Robotics retaining fixture is attached directly on the robot in two steps: simply place the Velcro around the robot arm and fix it. “Thanks to the Velcro fastener, the user has the opportunity to use the new retaining fixtures without any tools on any robot of their choice. Thanks to the flexible plastic, they can also be installed on another cobot at any time,” explains Matthias Meyer, Head of Robotics Industry Management at igus. “Since we manufacture the clamps by injection moulding, they are very cost-effective.”

Free choice for safe cable guidance

The new Lean Robotics retaining fixture will be available in three versions: the standard version has two continuously adjustable Velcro straps in a universal size and a rubber lining inside, so that the straps are fixed on the arm without the risk of slipping. This option is also available with a mounting bracket with and without strain relief. In a third option, the retaining fixture can also be equipped with a protector for additional security. The new retaining fixtures are suitable for use with the triflex R series TRC/TRE/TRL 30, 40 and 50 as well as for all commercially available protective hoses with different diameters.