Now in series production: igus presents new durable skate wheels, pulleys and roller adapters

October 7, 2025

Lubrication-free and wear-resistant iglidur rollers have a service life that is up to six times longer than that of solutions made of POM or PA

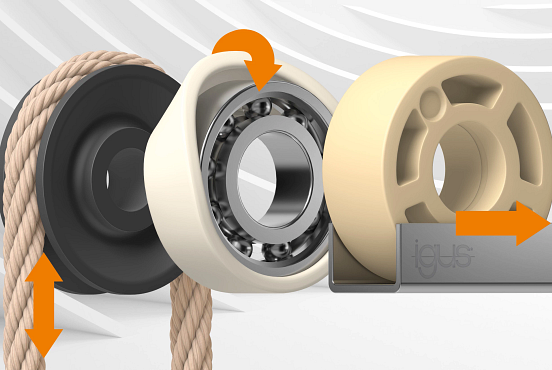

Three at one fell swoop: due to high demand, igus is launching new pulleys, skate wheels and roller adapters in series production, which were previously only available as customised products. Manufactured from high-performance plastics, the new components are an economical alternative to classic metal counterparts in numerous applications. They are lubrication-free and insensitive to dirt, durable, maintenance-free, vibration-dampening and ensure a quiet operation.

Design engineers regularly require reliable pulleys, e.g. to realise height-adjustable workstations, mobile medical devices or compact lifting systems. “Traditionally, pulleys with lubricated ball bearings are used, but they can become a weak point in the system as they are susceptible to contamination,” says Lars Kleist, Development Engineer for Rollers at igus. The plastics specialist has therefore launched an alternative on the market: pulleys made from the high-performance plastic iglidur JB. Their advantage: thanks to the solid lubricants integrated in the material, the rollers run directly on the shaft without additional lubricants – which makes them dirt-resistant, maintenance-free and durable. According to tests in our in-house laboratory, iglidur JB is around four times more wear-resistant than POM pulleys. To ensure that the iglidur rollers also wear the cable as little as possible, igus has optimised the geometry of the pulley. For example, a specially moulded groove recess ensures that the rope is in contact with as much of the surface as possible. “After their installation, pulleys thus become a component that design engineers no longer have to worry about,” says Kleist. The maximum recommended surface pressure is 35MPa. The pulleys are now available in three sizes for ropes that are 1mm, 1.5mm and 3mm wide.

Skate wheels made of high-performance plastic for linear adjustments

Another new product in the igus range are skate wheels made of the high-performance plastic iglidur J. They are suitable for linear adjustments, for example for closing machine doors, in movable control panels or compact protective enclosures. Until now, lubricated metal ball bearing rollers were often used in these cases. “Metal rollers are very heavy, so that they require a higher drive force when the axis are moving. They also react sensitively to dirt, are prone to corrosion under certain circumstances and can cause damage to the running rails when subjected to continuous load,” explains Kleist. The new skate wheels made of the tribologically optimised and lubrication-free material iglidur J, on the other hand, are dirt-resistant, corrosion-free, gentle on the rails – and suitable for surface pressures of up to 10MPa. According to laboratory tests, they are also around six times more wear-resistant than skate wheels made of POM. While the skate wheels were previously only available as special parts, igus is now launching them as batch-produced components due to increasing demand. They are currently available with outer diameters of 19 to 40mm and can be replaced one-to-one with standard ball bearing rollers without any changes to the design.

Polymer roller adapters minimise running noise and wear

If design engineers want to continue using metal skate wheels, igus has found a way to increase the service life of running rails by means of a small intervention. This is where the new roller adapters made from the high-performance plastic iglidur P360 come into play. Users can clamp their skate wheels into the roller adapters in just a few simple steps. This means that metal no longer runs on metal, but on plastic. This protects the running rail and consequently reduces maintenance work. “Our laboratory tests have proven that the iglidur P360 roller adapters are up to three times more wear-resistant than conventional PA roller adapters,” says Kleist. “The material is particularly cost-efficient and resistant to shocks and impacts. Last but not least, it allows for significantly quieter running.” The skate wheels are available with outer diameters of 19 to 48mm.