New triflex TRX energy supply system revolutionises 3D motion of robots

Published on: 10th May 2021

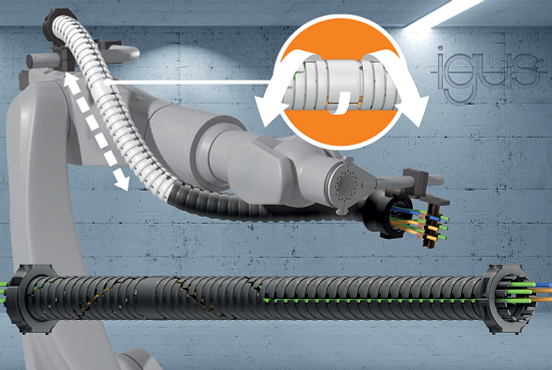

Telescopic triflex TRX energy chain from igus saves space on the robot and ensures a retraction length of up to 40 per cent

To ensure that cables on industrial robots can be guided in motion safely, easily and compactly, igus has now developed the four-dimensional triflex TRX energy chain. The new design study replaces classic robot hose packages and retraction systems. Special feature: 40 per cent retraction length ensured by a unique telescopic mechanism inside the chain. This allows users to save space on the third axis of their robot, up to 83 per cent weight and high costs for retraction systems.

The three-dimensional triflex R energy chains from igus are widely used in the industry for fail-safe guidance of cables and hoses on robots. Retraction systems have so far been used on the third axis to ensure that no loops are created during the movement of the energy chain system which could hinder the robot. “However, the axes on the robots offer less and less space, so a new solution was needed”, says Jörg Ottersbach, Head of the e-chains Business Unit at igus GmbH. No sooner said than done, the triflex TRX system was developed based on the triflex R energy chain. This is a four-dimensional energy chain in which the retraction system is already integrated. “With TRX, we created a space-saving chain that can be fixed directly and compactly on the third axis. The energy supply twists into itself, lengthens and shortens spirally as in a telescopic pull-out, by up to 40 per cent”, says Ottersbach. For this purpose, igus relies on a screw connector system in the unique mechanism as well as on an integrated reset band. The band brings the chain links back to their starting point time and again, and thereby the retraction force can be adjusted. The cables are placed in the chain in the form of a spiral and are guided safely in the movement with the help of the chain. In addition, the cables and hoses are fastened in place in the middle of the TRX so that they do not leave their position when the chain is pulled.

83 per cent weight saving

Compared to other retraction systems, the user saves up to 83 per cent weight and requires less than half the space. In this way, the performance of the robot can be further improved, and costs are significantly reduced by dispensing with an additional retraction system. TRX can be easily connected to existing TRE series triflex R chains. As with triflex R, the cables can be quickly filled into the energy chain from the outside. igus will present the new TRX to interested parties from 5th May 2021 at its newly launched real-virtual trade show.

You can find more information and a video of the operation of the TRX at:

https://www.igus.eu/info/triflex-r-trx