Maximum performance in the smallest of spaces thanks to new miniature linear module with lead screw drive

January 14, 2026

Compact solution from igus allows for stroke lengths of up to 300mm for linear movements in medical technology, laboratory automation and equipment manufacturing

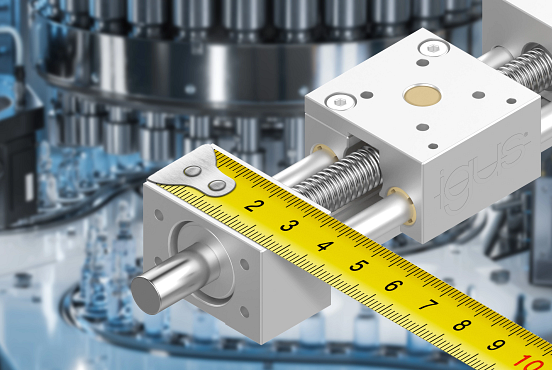

Design engineers in medical technology and laboratory automation often face a problem: linear modules for positioning tasks with stroke lengths of over 200mm quickly become bulky, run unevenly due to the small lead screw diameters and do not fulfil the strict hygiene guidelines because of the lubricating grease. igus has therefore launched drylin SLW-0620-Ds08. The compact linear module with lead screw drive allows for smooth stroke lengths of up to 300mm, operates completely without lubrication and is PTFE-free and tested for PFAS.

The new drylin SLW-0620-Ds08 miniature linear module is suitable for installation in automation solutions with limited installation space, for example in laboratory robots with moving pipetting heads that automatically pick up, distribute and deposit samples. The module is only 22mm high and 32mm wide. “Many users are looking for compact linear modules that work quickly and smoothly both with short stroke lengths and at well over 200mm and do not require lubricating grease,” says Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “Our new, space-saving and lubrication-free SLW-0620-Ds08 miniature linear module is the solution.” It is now available in silver anodised and black anodised.

Stroke length of up to 300mm, service life of 877,000 double strokes

Despite its compact design, the new miniature linear module allows strokes of up to 300mm. “Many linear modules on the market are much bulkier in this area,” emphasises Hornung. Another advantage: the new solution permits speeds of up to 200mm/s. This is made possible by a dryspin® high helix thread, in which the pitch is so high that one rotation corresponds to a pitch of 40mm. “We opted for a lead screw with a slightly larger diameter of 8mm to ensure stiffness and smooth operation at these speeds.” The maximum static axial load capacity is 50N, the maximum radial load capacity amounts to 200N. “Laboratory tests have proven that the new linear modules achieve a service life of 877,000 double strokes under a load of 30N,” explains the linear technology expert.

Lubrication-free and successfully tested for PFAS

The drylin SLW-0620-Ds08 linear axis is designed for use in areas with high hygiene requirements. To achieve this, the system does not use lubricants. The carriage for the superstructure moves on plain bearings in the aluminium rail, which are made of high-performance plastic. The solid lubricants incorporated into this material make low-friction dry operation possible without grease as this quickly becomes a contamination risk with conventional metal bearings. “We also rely on the iglidur JPF material for all bearing points, which is PTFE-free and tested for PFAS,” says Hornung. “Users of the new PTFE-free and PFAS-tested solutions are therefore already prepared for possible stricter regulations by the EU. The combination of SLW miniature axis, dryspin® lead screw technology and iglidur JPF not only reduces the risk of failure, but also fulfils the growing customer demand for more sustainability.”