Greater efficiency in production with igus lightweight iglidur polymer linear bearings

Published on: 24th June 2021

New, cost-effective drylin linear bearing ensures fast, lubrication-free movements

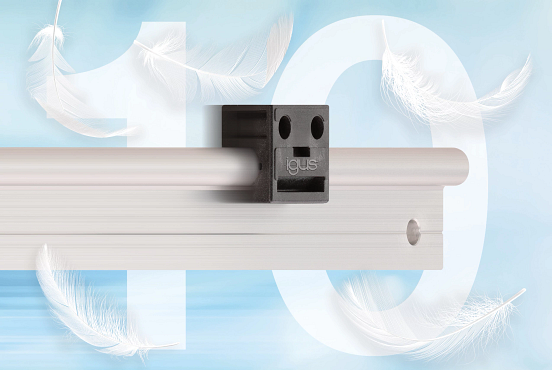

igus, a motion plastics specialist, showcases what plastics can do with its first drylin W linear bearing made entirely of tribo-polymers. The linear bearing has been developed specifically for linear movements. At just ten grammes, it is quick to install, vibration-dampening, lubrication-free and ideal for transportable applications. The fact that it is injection moulded makes it very cost-effective. The injection moulding-optimised design also reduces its weight, lowering the necessary linear system drive energy.

Durable, lightweight and low-cost: the new drylin W linear bearing from igus. It is made entirely of iglidur polymer, so it can be manufactured quickly, simply and cost-effectively with injection moulding. The liner and linear housing are combined in a single component that simplifies handling, from storage to installation. The iglidur polymer bearing weighs up to 84% less than classic linear bearings with their metallic housings. There is thus less mass to move, so force, motor output and energy consumption falls. The slim bearing, just ten grammes at Installation Size 10, has several advantages for those new to linear technology who need a simple linear guide for applications, such as adjusting tabletop devices, cameras, sensors or monitors. The bearing is made of iglidur JB, a tribologically optimised high-performance polymer, so it needs no lubrication or maintenance and is durable and resistant to dust and dirt. The black material is remarkable for its very low coefficient of friction in dry running and very low stick-slip tendency. The polymer bearing can handle loads of up to 25 newtons with ease, as tests performed in our 3,800 square metre in-house laboratory in Cologne show. It is also impact-resistant and robust while remaining elastic and damping so that it can absorb and dissipate vibrations.

Cost-effective econ system with an elegant design

The new bearing can be installed very easily on any drylin W single rails or double rails. If the user is looking for a cost-effective linear guide, igus’s clear anodised drylin W WS-CA aluminium rails are a good choice. Combining the two materials – silver aluminium and black bearing material – gives the user a complete solution with a simple, elegant design.

You can find information about the new iglidur polymer bearing here:

www.igus.eu/wjbmp