For highest precision and rigidity: new drylin linear bearings for shafts

Published on: 13th May 2021

Bearings made of iglidur W360 high-performance polymer ensure precise and easy movements in linear technology

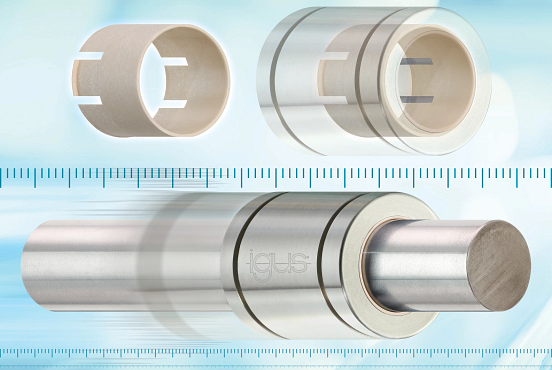

In order to be able to move linear bearings on shafts with high precision, igus has now developed the W360CM series. The new polymer linear bearings consist of an aluminium housing and a thin liner, which ensure smooth and quiet operation combined with high rigidity. The bearings have hardly any clearance and allow precise movements. Thanks to the use of iglidur W360 high-performance polymers, the user does not need external lubrication. The dimensions of the new series match metallic ball bushings, so that they can be easily converted 1:1.

Linear guides are used wherever goods or objects need to be moved from A to B, or equipment or machines need to be adjusted. Precision often plays a major role for users, for example in microscope tables or in X-ray equipment. Therefore, the motion plastics specialist igus has now developed the linear plain bearing series W360CM. It ensures the highest precision and rigidity in drylin R shaft guides. The long-lasting sliding elements of the bearings are characterised by a thin wall thickness and high strength. They are produced cost-effectively in injection moulding from the high-performance polymer iglidur W360. The material enables very quiet and smooth operation. The operating temperature range is between 0-50 degrees Celsius. Due to the thin wall thickness and the higher material strength, the linear bearings ensure a low bearing clearance at the operating point due to reduced elasticity. The new bearings – like all plain and linear bearings from igus – are free of lubrication and therefore free of contamination and maintenance.

New polymer bearings convince in the test

The W360CM linear bearings can be easily mounted in all drylin housings as well as in all standard receptacles for linear ball bushings. This means that ball-based solutions can be converted 1:1 without a construction wall using the maintenance-free solution. The design of the new linear bearings is simple: the liners are pressed into the housing until a pre-loaded snap hook is inserted into a groove. Thus, the films are secured against displacement even under high loads and temperatures. The new drylin R series was also able to convince in tests in the in-house 3,800 square metre laboratory at igus in Cologne. Gauge measurements to check bearing clearance and precision showed that the W360CM series bearings performed far better than coated linear bearings.

Learn more about the new bearing at:

https://www.igus.eu/info/n21-drylin-linear-liners?L=en