For a neatly sliding bag: new igus coating powder for food technology

January 28, 2021

FDA-compliant polymer powder IC-05 with four times longer service life than IC-01 ensures wear-resistant sheet metal

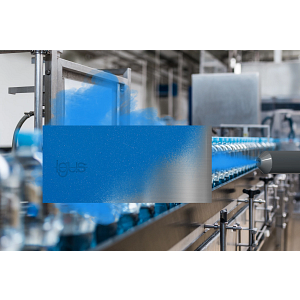

Whether in dosing systems, on conveyor belts of filling systems or in labelling technology: you will find sheet metal and parts that are exposed to friction and wear in all these places. To increase the service life of the metallic components, igus has now developed a new coating material. The sprayed-on IC-05 tribo-polymer protects sensitive and small bearing points as well as sliding surfaces. It is optically detectable due to its blue colour and is approved for use in food technology. In the test, the material was able to convince with a four times longer service life than the coating powder IC-01.

Nowadays, it is impossible to imagine the food industry without automated systems. But what happens if a bottle falls over in the filling line or a packet soup gets wedged in the parts chute and tears open? Scenarios that lead to unplanned plant shutdown, cost time and money. Moving machine components with low coefficient of friction are in demand here. In order to give guide plates, metallic slides or even parts with complex geometries a high wear resistance, igus has now developed a new coating material especially for use in food technology. The high-performance IC-05 polymer complies with FDA requirements and EU10/2011 regulations and is therefore ideally suited for contact with food. Its blue colour makes it optically detectable. The material significantly reduces the coefficient of friction of the coated parts and increases the service life and availability of the equipment. It also improves product safety and reduces costs. Lubricants can be dispensed with completely. The powder material can either be sprayed onto the desired components by the user or by igus. Layer thicknesses of 60 to 120 µm are possible. “Especially for places where there is no space for a plain bearing, a coating of the moving parts that are exposed to wear is a good idea”, explains Stefan Loockmann-Rittich, head of the iglidur plain bearing technology business division at igus GmbH.

Laboratory test reveals four times longer service life

igus tested the durability of the coated parts in its own 3,800 square metre laboratory in Cologne. Here, a part coated with IC-05 was compared with an identical part coated with the standard material IC-01 in various test set-ups. The FDA-compliant component impressed with a four times longer service life. In addition to IC-05, igus offers five other coating materials, for example, for applications in the high-temperature range or with high chemical resistance.

Learn more about the igus coating materials at:

https://www.igus.eu/info/plain-bearings-coating-iglidur?L=en