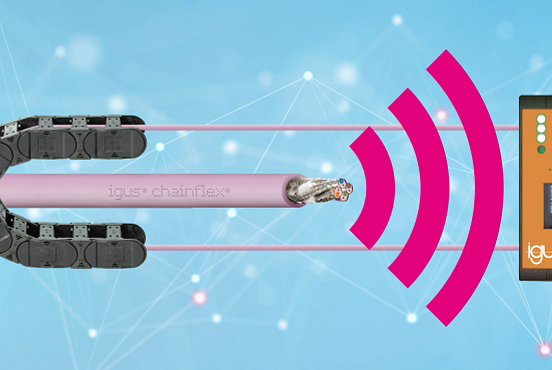

Detect cable stress at an early stage and more precisely than ever before with i.Sense CF.D

Published on: 2nd December 2022

The igus monitoring module with its unique status display measures the distance to the cable’s risk area

Maintaining heavily used and hard-to-reach bus cables faster than ever is what i.Sense CF.D, the igus monitoring module, can do – and nothing else in the world can. The module automatically recognises the positions of stressed areas in a cable and shows them very precisely in metres. The new optical status display now enables users to intervene quickly in a targeted manner, avoiding time-consuming and costly troubleshooting.

Monday morning in a car factory: a robot welds body parts together. Thanks to a seventh axis, the robot moves in a large work area, its data supplied with Ethernet cables. A technician opens the welding robot’s control cabinet to see whether all Ethernet cables are working correctly. But the i.Sense CF.D monitoring module’s coloured signal lamps show that the transmission quality in one cable is weakening. Three different types of Ethernet cable are often used on the robot: a static cable from the control cabinet to the seventh-axis e-chain, a chainflex bus cable in the e-chain system and a chainflex robot cable for torsional movement on the robot. External influences can cause transmission quality malfunctions here. But the cables are very long and difficult to reach in many places. “In such cases, searching for and fixing errors is often time-consuming and expensive,” says Richard Habering, Head of the smart plastics Division at igus, and he knows from experience. “We have therefore developed a new function for the i.Sense CF.D monitoring module that is so far offered nowhere else in the world: an optical status display with precise information on the distance to the suspected fault location.”

Simply read the risk area from the OLED display

i.Sense CF.D continuously measures transmission properties and various electrical parameters over millions of cycles. The system thus not only detects data losses in real time, but also identifies the position of the stressed area of the cable very precisely. “This information, which appears directly on the module’s OLED display, enables users to identify the risk area faster and in a more targeted manner than ever and immediately replace the cable for the segment in question without trial and error – and without additional tools or software costs.” i.Sense CF.D can be set up just as quickly. Simply install the module in the control cabinet and connect the cables to be monitored, then start right away.

Predictive maintenance with the i.Cee module

It is just as easy to add i.Cee to the system. The multifunctional module is compact, takes up hardly any space in control cabinets and, like i.Sense CF.D, can be set up in just a few simple steps. A minor intervention allows automatic cable monitoring, fault management and predictive maintenance planning via a digital control system. All live cable parameters – such as number of strokes and running performance in kilometres – can be aggregated on a dashboard. Technicians usually have only two options for servicing cables that are subject to heavy mechanical stress. They can be reactive, replacing cables when they are already defective, but this usually means unnecessarily long, expensive downtimes. Or, as a precautionary measure, they can replace cables at specific intervals, accepting the higher costs when cable service life is not exhausted. i.Cee changes all that. If defined limits are exceeded, the system can automatically trigger an alarm or an emergency stop of the facility. This prevents immense consequential damage or even total failures, which can cost tens of thousands of euros in automotive production or the crane industry, for example. The i.CEE module also automatically calculates the most economical time for maintenance operations and cable changes. “It is therefore ideal for reducing both maintenance costs and downtimes. Investment in a CF.D module pays for itself in just a few months, with an ROI of over 500% per year.”