Additive manufacturing meets industry 4.0: igus makes 3D printed tribo-components intelligent

Published on: 19th November 2020

A world’s first: sensors integrated in printed components indicate maintenance requirements and warn of overload

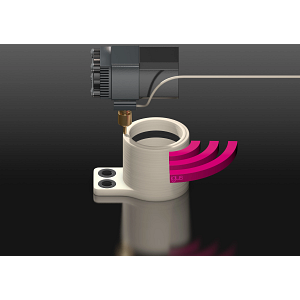

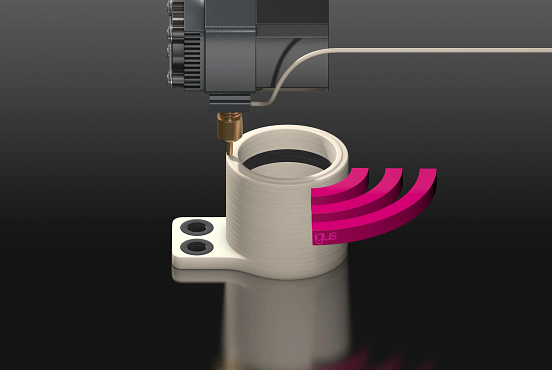

Even today, 3D printed wear-resistant parts from igus often have the same service life as original parts. Now igus goes one step further and makes the printed components intelligent. Manufactured in filament printing, they warn against overload and report their maintenance requirements. The special feature: for the first time, the sensors are directly “printed into” the parts. As a result, they not only have extremely short delivery times and low costs but also feature useful Industry 4.0 options.

Additive Manufacturing and Industry 4.0 – two themes that are changing the industry forever. igus engineers have now succeeded in combining both in a single production step: for the first time, sensors are printed into the additively manufactured tribo-component using multi-material printing. “We have now achieved a real breakthrough with the smart 3D printed bearing”, says Tom Krause, Head of Additive Production at igus. “In this way, predictive maintenance is also possible for special parts in a cost-saving manner.” Long before the failure, the intelligent 3D printed component signals that a replacement is imminent. It can also detect overload in order to stop the application immediately and prevent further damage to the bearing position and the entire system.

Wear or load are monitored

igus has been producing intelligent wear-resistant parts for energy chains, plain bearings and linear guides since 2016. At the start, plain bearings were manufactured from iglidur I3 in laser sintering and the intelligence was subsequently introduced in a second processing step. In this case, however, the production of intelligent special parts in small quantities is complex and expensive, as the downstream work steps are very specifically designed for the respective component. Using a new process, igus developers are now able to produce such intelligent wear-resistant parts in just a single work step. No further processing steps are necessary and intelligent special wear parts can be produced cost-effectively from 5 working days. The sensor layer is applied to those parts of the component that will be subjected to load. Wear-resistant components with integrated sensors are created using multi-material printing. The components are manufactured from iglidur I150 or iglidur I180 filaments and a specially developed electrically conductive 3D printing material that bonds well with the tribo-filament.

Currently, two areas of application are possible: if the electrically conductive material is located between the layers subject to wear, it can warn against overloading. Because if the load changes, the electrical resistance also changes. The machine can be stopped and further damage can be prevented. To determine the load limits, the bearing must be calibrated accordingly. If, on the other hand, the conductor track is embedded in the sliding surface, the wear can be measured via the change in resistance. Predictive maintenance is possible with the 3D printed component. The lubrication-free and maintenance-free tribo-component announces when it needs to be replaced, avoiding system downtime and enabling maintenance to be planned in advance. If the 3D printed components are also used in the pre-series stage, the collected wear or load data provide additional information about the service life of the individual component or the planned application in the series. This makes it easier to adapt and optimise the development process.

Interested parties can register for a beta test here:

https://content.communication.igus.net/en/3d-isense-beta-tester

This is just one of many 3D printing innovations that igus is presenting this autumn. For all those interested, igus offers individual guided tours at the virtual new products trade show, and also further information at https://www.igus.eu/info/3d-printing-fair?L=en