A smart box! New igus module for predictive maintenance

Published on: 27th May 2021

i.Cee:local module predicts the service life of machinery and equipment, making maintenance efficient and predictable

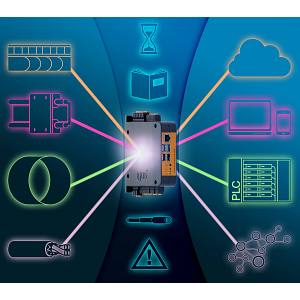

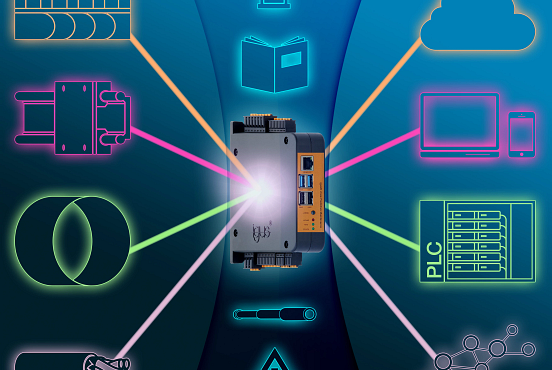

With the i.Cee:local module, igus has now developed a new home for its smart plastics software. The module calculates the remaining service life of the energy chain, cable, linear guide and plain bearing during operation. This allows the service life of the system to be optimised, faults to be detected and rectified at an early stage, and maintenance to be planned in advance. With its multi-connectivity, i.Cee:local can be integrated via the Internet or without IoT connectivity via the local network, depending on customer requirements.

smart plastics sensors from igus: they monitor abrasion, measure the pull/push force and provide information about an imminent overload. But how does the maintenance manager get concrete information about the condition of the system? The new solution from igus is the i.Cee:local. The intelligent module bundles the data of all smart plastics systems used and prepares it for the maintenance engineer. i.Cee:local has two functions: it is the home of the open source i.Cee software, the brain of smart plastics. For the first installation, the software is first parametrised and thus optimally adapted to the specific application with the help of the service life algorithms from igus. “The service life forecast, which we determine on the basis of millions of test data in our in-house 3,800 square metre laboratory, is compared and adjusted during operation with the values actually determined, so that a real-time service life statement can be made about the durability of the machine and system”, explains Richard Habering, Head of the smart plastics Business Unit at igus GmbH. With i.Cee:local, maintenance can be planned in advance, malfunctions can be detected in time and plant downtime can be avoided. The costs of an early retrofit can be reduced through the maximum use of igus components, and spare parts can also be ordered automatically at an early stage. The use of i.Cee:local is suitable for all igus smart plastics products, from plain bearings up to chains.

Multi-connectivity for easy overview

The second important specification of i.Cee:local is its multi-connectivity. The possibility of seamless integration into the designated network environments allows the implementation of various Industry 4.0 use cases. The data of the i.Cee:local module can be accessed either via a display on the system, via a cloud solution or an IoT dashboard, as JSON/MQTT protocol, on the intranet, via the REST API interface or directly via SMS or email. “No matter whether online or offline, depending on the customer’s requirements, the data can be accessed quickly and easily by the maintenance staff, thanks to the i.Cee:local module”, says Richard Habering.

Find out more about the i.Cee:local at:

https://www.igus.eu/info/i-cee-plus-2