4K for 3D: igus offers multi-material printing for multifunctional components

Published on: 6th May 2021

The motion plastics specialist continues to expand its 3D printing capacities for durable, wear-resistant and complex components

If a component is to have several properties, it usually has to be manufactured in several steps. But such production can quickly become cost-intensive for small quantities. It is precisely for this reason that igus now offers multi-material printing with up to four materials. This allows multifunctional and wear-resistant special parts to be manufactured quickly and cost-effectively in just one step. To this end, igus has further expanded its 3D printing capacities and its range of materials for the FDM process.

3D printing of individual wear-resistant parts with different materials offers the user great design possibilities. At the same time, multifunctional components significantly reduce the manufacturing process. Therefore, igus has been offering the production of durable special parts in multi-material printing with two materials since last year. In this way, wear-resistant but at the same time resilient components, as well as intelligent special parts, can be produced. This service has now been expanded by motion plastics. igus can now use up to four materials in a single process to manufacture multifunctional components. “For this purpose, we have expanded our 3D printing production and now also offer new materials that can be processed specifically in multi-material printing”, explains Tom Krause, Head of Additive Manufacturing at igus GmbH. “For example, we can produce parts for equipment, tool or special machine construction cost-effectively with no minimum order quantity in just a few days.”

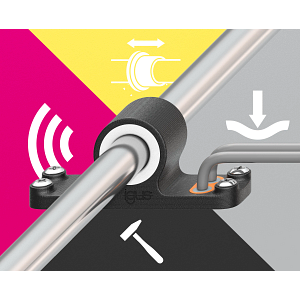

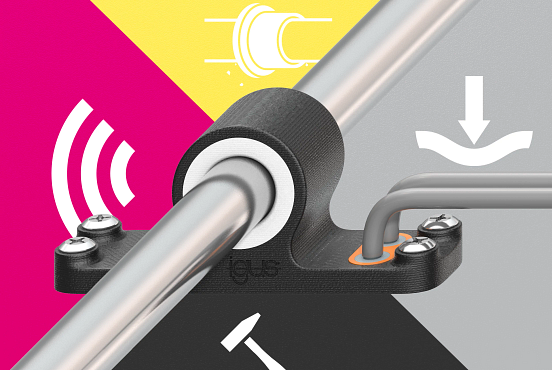

Multi-material printing for bearings with the best specifications

The igus materials for multi-material printing have different specifications. The iglidur tribo-filament makes components low-friction, maintenance-free and up to 50 times more abrasion-resistant than regular 3D printing materials. With iglidur I160-EL, igus is now offering a new elastic material that can be printed in the individual bearing, as a seal, for example. igumid P150, on the other hand, is the new 3D printing filament for multi-material printing, which ensures high strength (87 MPa flexural strength) of the component. Especially for the additive manufacturing of intelligent components with integrated sensors, igus offers two further smart materials: sigumid P and sigumid F. The latter is printed onto the bearing and sends a signal via a normally closed contact when the wear limit is reached. By contrast, sigumid P is used to alert of an overload in the bearing. This is because when pressure is applied to the bearing, the shape changes and so does the resistance. “4K printing now makes it possible to combine all the specifications of the different materials – wear-resistant, strong, elastic and intelligent – in one complex component”, Tom Krause sums up.

More information on multi-material printing can be found at:

https://www.igus.eu/info/multiple-component-3d-printing?L=en