igus meets metaverse: the plastics specialist brings sales and engineering to virtual reality

Published on: 1st December 2022

Salespeople, engineers and customers are to work together in the iguverse

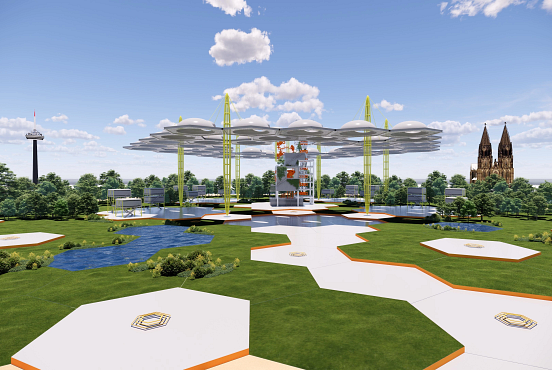

Take a closer look at products from all sides with VR glasses. Work with engineers and materials experts in virtual reality to plan machines, plants and vehicles. Fast and location-independent. The iguverse is igus’s parallel digital universe that prepares sales and engineering for the metaverse.

Fortnite – a computer game that enables people to participate in social events in a 3D simulation – demonstrates how powerful a parallel digital universe can be. 12.3 million players gathered in a virtual space in April 2020, when rapper Travis Scott gave a digital concert with an avatar. A parallel digital universe could have similar importance for industry and commerce. “We are pursuing the vision of the iguverse, a virtual space in which all of our products can be experienced as digital twins, but that is not all,” says igus CEO Frank Blase. “Customers from all over the world will have the opportunity to work with engineers and project managers in iguverse to develop machines, systems and vehicles and to immerse themselves projects and applications. This will save time and money.”

“Customers are up to nine times as likely to remember experiences in virtual reality”

Sales in virtual space: visitors to the IAA Transportation 2022 trade show in Hannover got a foretaste. At the igus stand, they could put on virtual reality glasses and, accompanied by igus employees, take a first look at the beginnings of the igus metaverse. In future, they will look at 3D models of products such as energy chains from all sides in a 360-degree panoramic view. They will experience the igus infrastructure, such as the 3,800-square-meter test laboratory in Cologne, without having to travel, and will be able to immerse themselves in applications that use igus components. Such applications range from a plastic bicycle to a futuristic minivan with iglidur plain bearings, drylin linear guides and e-chains to an oil platform that uses the modular e-loop energy chain system. These impressions are not nearly as impressive and lifelike when conveyed with traditional media such as catalogues, brochures and multimedia presentations or even videos and previous 3D objects. “The iguverse represents a new way of presenting, selling and engineering,” says Blase. “For many, the metaverse is still uncharted territory. We want to learn more, too, and are therefore travelling this path with our customers. It has plenty of potential for future sales. For example, salespeople and customers could put on VR glasses during customer visits and immerse themselves in the iguverse. Studies show that customers are up to nine times as likely to remember experiences in virtual reality and thus understand things better,” says Blase.

Smooth, time-saving engineering in virtual reality

But digital twins of products and infrastructure are only one stage of expanding into the iguverse. In future, customers, engineers, and material experts will meet as avatars in digital space, where they will carry out entire engineering projects – faster and smoother than is possible in just the physical world. At a further stage, igus is considering expanding the iguverse to include a B2B platform for other manufacturers. They can then also present machines and systems in virtual space, provided they use igus components. This is a megatrend according to Gartner, a US market research firm. They think that digital channels will represent 80% of B2B sales interactions between suppliers and buyers as early as 2025. igus, however, will use the B2B platform to create a growing reference database for motion plastics, one that can also be accessed virtually.

Selling digitally with augmented reality

igus is also using a new form of digital sales and presentation with augmented reality. One example of this is the triflex TRX energy chain series. Sales staff and customers used to have few opportunities to look inside a closed sample chain. Some mechanical principles that are particularly unusual in the triflex TRX had to be left to the imagination. Augmented reality changes all that. If employees activate the software on their smartphones using a QR code on the e-chain, the application overlays the product on the screen with an animated virtual twin. This enables a kind of X-ray view of the mechanism inside the chain. Products that require explanation thus become clear.